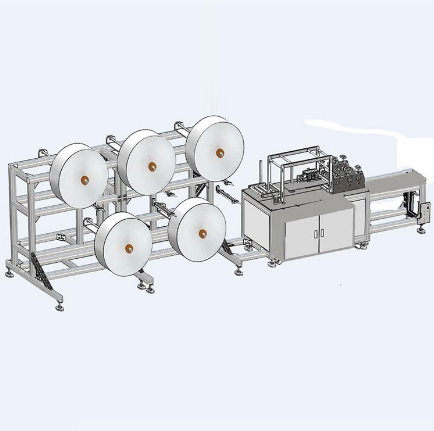

Equipment introduction

The high-speed film machine adopts ultrasonic welding technology to automatically produce 2-5 layers of butterfly mask body (such as 3M company's 9001, 9002 series masks). Automatically complete the operation, manual feeding and automatic feeding; the included processes include coil feeding, nose beam feeding, mask pattern welding, mask cutting, and main body cutting.

The equipment produces the main body of the butterfly mask through the cooperation of the feeding system, the fabric forming system, and the nose beam forming and cutting system. In order to meet the market demand, the mold can be simply replaced to adapt to the production of various types of butterfly mask bodies.

Technical parameters:

| Model | SM-KN95 |

| Work power | AC220V±5%,50HZ |

| Equipment power | 4KW |

| Capacity | 100-120pcs |

| Material Max width | 260mm |

| Nose bridge Method | Build-in Nose bridge |

| Weight | 400kg |

| Size | 6200x1000x1600mm |

Sample: